0

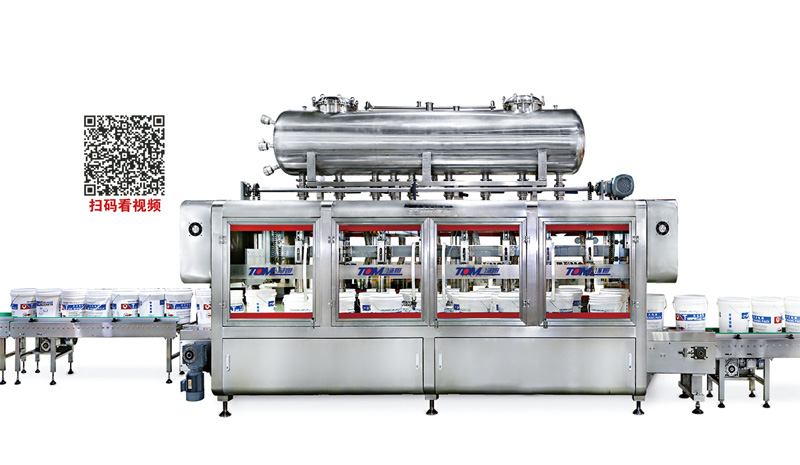

0Automatic lubricant /coatings weight filling machine :

Specifically for the agrochemical enterprises to provide the most provincial, most stable, most advanced packaging smart line, and strive to make Tom's products achieve practical, beautiful, humane, stable, thick and solid, humanization, to make due contributions for China and the world's.

E-mail: chiss@cn-tom.com

Mobile: 0086-18015095117

Tel: 0086-18015095117

WhatsApp: +86-15895023711

Add: No.99, Rulin Town, Jintan District, Changzhou City, Jiangsu Province, China.