0

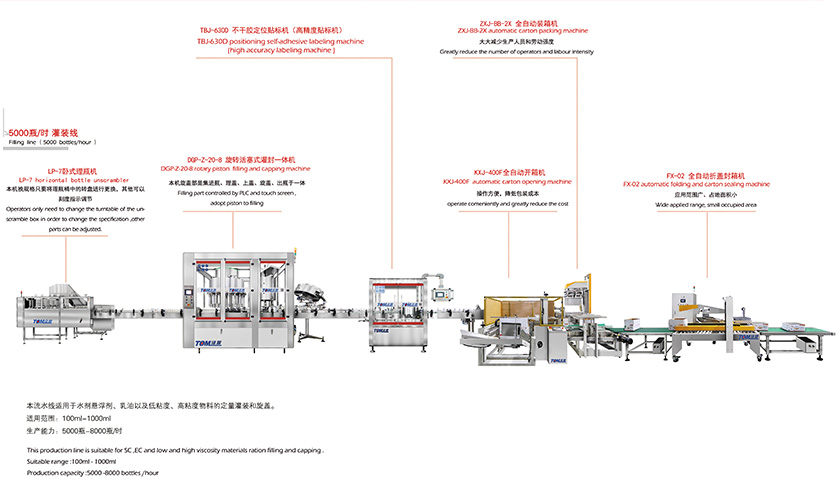

0This production line is suitable for SC ,EC and low and high viscosity materials ration filling and capping .Suitable range :100ml - 1000mlProduction capacity :5000 -8000 bottles /hour

LP-7 horizontal bottle unscramblerOperators only need to change the turntable of the unscramble box in order to change the specification ,other parts can be adjusted.

DGP-Z-20-8 rotary piston filling and capping machineFilling part controlled by PLC and touch screen ,adopt piston to filling

TBJ-630D positioning self-adhesive labeling machine (high accuracy labeling machine )

KXJ-400F automatic carton opening machineoperate comeniently and greatly reduce the cost

ZXJ-BB-2X automatic carton packing machineGreatly reduce the number of operators and labour intensity

FX-02 automatic folding and carton sealing machineWide applied range, small occupied area

Specifically for the agrochemical enterprises to provide the most provincial, most stable, most advanced packaging smart line, and strive to make Tom's products achieve practical, beautiful, humane, stable, thick and solid, humanization, to make due contributions for China and the world's.

E-mail: merry@cn-tom.com

Mobile: 0086-15961418794

Tel: 0086-15961418794

WhatsApp: +86-15961418794

Add: No.99, Rulin Town, Jintan District, Changzhou City, Jiangsu Province, China.