0

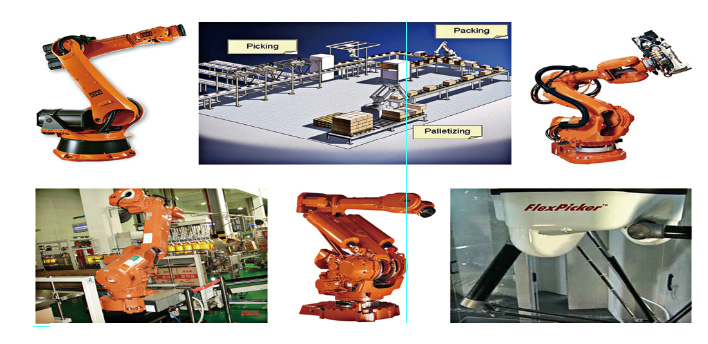

0Palletizing robot designed mainly for packaging applications, although compact body ,it can be integrated in a compact packaging machinery, but you can meet all the motion control ,the robot is very suitable for flexible packaging systems ,greatly reducing the packaging cycle time. Has a very high accuracy ,plus excellent conveyor tracking performance ,whether it is a fixed position of the operation ,or the movement of the operation ,the accuracy at first class. It is small and fast, been optimized specifically for packaging applications ,robotic automatic is the inevitable choice. With a full set of auxiliary equipment(air and the signal from the integrated system to catch feeder),can match with packaged software ,mechanical integration is simple, the programming is very convenient. Using the most advanced 4-axis design ,with 3.15m and 250kg payload distance to the high-speed robots, it is very suitable for bags ,boxes ,crates ,bottles and packaging materials for packing and stacking applications. Boxing robots need to object to quickly and accurately move from to another (each one)applications ,it is the ideal choice. And it is with high precision of the system ,selecting only good robot body ,and ignoring the defective objects. Structure is very simple ,consisting of only few parts ,which is the program longer uptime reason than hard automation solutions. Mean time between failures(MTBF)of 135,000 hours. Similar fastest robot operation. Specially designed for fast quick and place,150times per minute to complete the action picked up, the corresponding cycle time of 0.4seconds. The maximum acceleration of 10g,IRB 340 robot is the world’s fasted accelerating current. The robot work cycle per minute up to 180 times. Hand picked payload weighing material 2kg. IRB 340 robot with a stainless steel version of the supply, suitable for demanding operating environment cleanliness. The robot uses the top of the installation ;do not take up interior space, and easy integration. After accompanied pick master software ,IRB 340 robot called the most powerful high-speed pick and place robots in flexible solutions.

● Reliability -long uptime

● Fast -short cycle times

● High accuracy-stable production quality parts

● Powerful -for a wide range

● Durable -suitable for harsh production environments

● Well universal -flexible integration and production

Specifically for the agrochemical enterprises to provide the most provincial, most stable, most advanced packaging smart line, and strive to make Tom's products achieve practical, beautiful, humane, stable, thick and solid, humanization, to make due contributions for China and the world's.

E-mail: chiss@cn-tom.com

Mobile: 0086-18015095117

Tel: 0086-18015095117

WhatsApp: +86-15895023711

Add: No.99, Rulin Town, Jintan District, Changzhou City, Jiangsu Province, China.